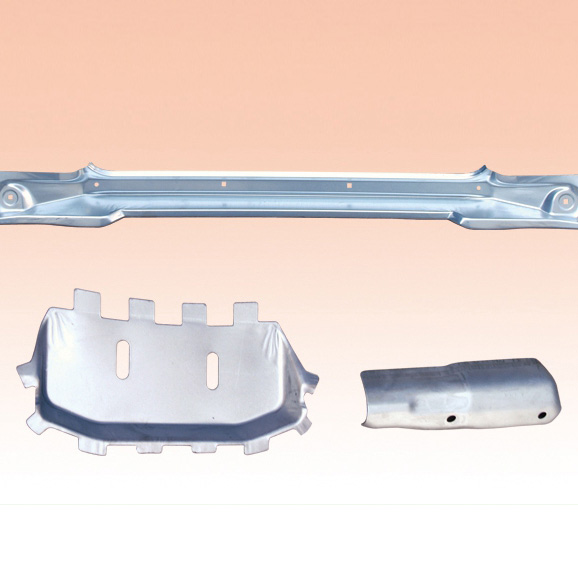

PRODUCTS

Add:No. 58 Fangbei Rd, Shijiazhuang 050011, Hebei province, China

Tel:+86 311 85319106

+86 13703116356

Fax:+86 311 68090963

Mail:hbkctc@sina.com

Material selection for zinc alloy die casting

Common zinc alloy materials are: 2ZnAl43, 2ZnAl41, 2znal40.5, 2ZnAl4, commonly used brands ZnAl925, ZnAl903, but ZnAl903 is better than ZnAl925.

In addition, some of the returned material is often used in die casting, the proportion of which must be controlled from 15% to less than 20%. Doping other components (such as silicon) is easy and will affect the adhesion of the coating. For castings with high feedback, hydrofluoric acid is used for activation during plating.

Blank inspection of coarse zinc alloy casting before plating

(1) Appearance: Check the blank surface for significant defects such as cracks, bumps, scratches, holes, etc. To determine the extent of these defects, the grinding process can be increased if mechanical means (polishing, polishing, etc.) can be used to remove them.

(2) Material inspection: check the grade of zinc alloy, understand the return rate, check the quality of die casting, place the work in an oven at 100-110 ° C for 30 minutes, and check if the surface is convex .

we are Cast aluminum manufacturers,If you want to buy Cast aluminum,pls contact us.

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China Tel: +86 311 85319106

Tel: +86 311 85319106  Mail:

Mail: