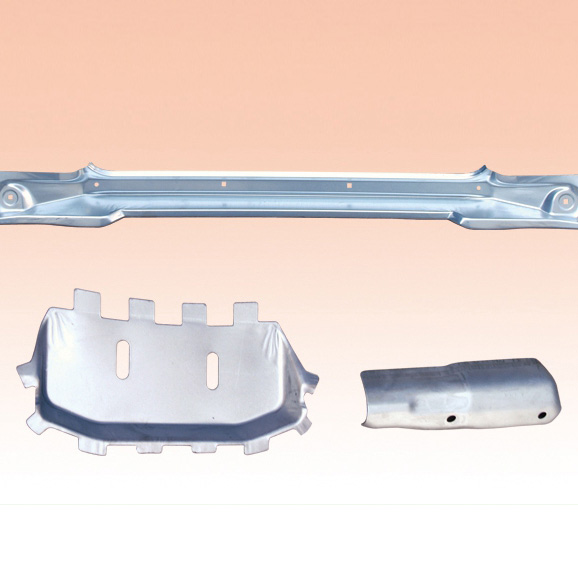

PRODUCTS

Add:No. 58 Fangbei Rd, Shijiazhuang 050011, Hebei province, China

Tel:+86 311 85319106

+86 13703116356

Fax:+86 311 68090963

Mail:hbkctc@sina.com

Zinc alloy die casting mold and die casting process design

Zinc alloy casting geometries, deep cavities, and other structures of blind holes in the design are avoided as much as possible. Thus, for designed parts, the appearance and use of the part is not affected, and the hole drainage solution is a convenient solution for gas. This allows the plating solution to be plated effectively and reduces the degree of contamination.

Design and die casting technology of zinc alloy die casting parts

The surface of the zinc alloy die-casting is a dense layer with a thickness of about 0.1mm and the inside is porous. In the mold design and die casting process, the surface of the workpiece should be as smooth as possible to reduce casting defects such as cracks, porosity, cold gaps, burrs and burrs.

At this time, it is necessary to avoid damage to the surface of the dense layer so that the porous substrate is exposed to the difficulty of electroplating and does not affect the quality of electroplating. Zinc alloy die castings often use release agents. Care must be taken with the use and release of release agents. Zinc alloy die casting

we are Cast aluminum manufacturers,If you want to buy Cast aluminum,pls contact us.

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China Tel: +86 311 85319106

Tel: +86 311 85319106  Mail:

Mail: