PRODUCTS

Add:No. 58 Fangbei Rd, Shijiazhuang 050011, Hebei province, China

Tel:+86 311 85319106

+86 13703116356

Fax:+86 311 68090963

Mail:hbkctc@sina.com

How to effectively control porosity defects in lost foam cast iron par

Effective control of blowhole defects in lost foam cast iron parts can be solved with the following points:

1. Choose the right model material

As a model material, a copolymer foam is used, and since the copolymer is decomposed by a zipper, the degree of gasification at one time is high, the ratio of a liquid phase is small, and a low molecular gas easily overflows from the coating. The density of mildew is as low as possible, provided that it is strong and smooth to reduce the total amount of gas generated. The pouring system uses a hollow straight runner, mechanically stops the metal liquid and is fitted with a filter to absorb and fill the combing flow. More stable.

2. Improve the air permeability of the coating

The particle size of the refractory aggregate must be appropriate. A composite suspending agent binder is used and the compounded coating has high and low temperature strength, abrasion resistance, easy to brush, no cracks, large exhaust capacity, good air permeability, uniform sintering , Unpacked. It is easy to peel and peel without getting wet or chemically reacting with metal liquid.

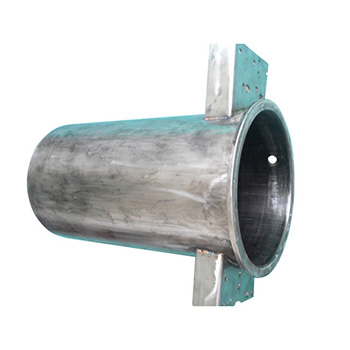

we are cast iron parts manufacturers,If you want to buy cast iron parts ,pls contact us.

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China Tel: +86 311 85319106

Tel: +86 311 85319106  Mail:

Mail: