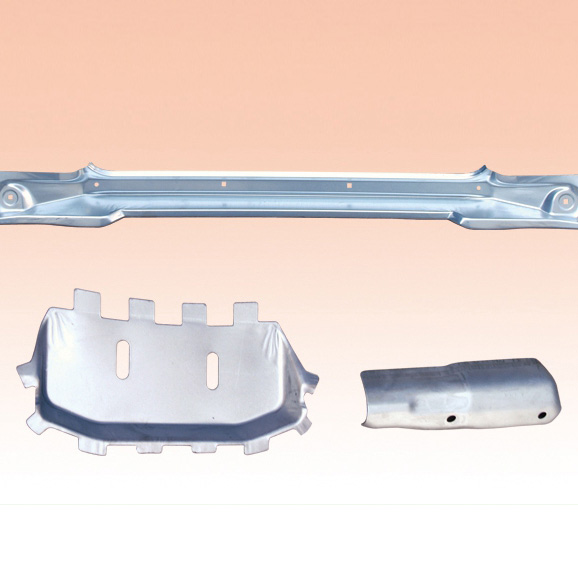

PRODUCTS

Add:No. 58 Fangbei Rd, Shijiazhuang 050011, Hebei province, China

Tel:+86 311 85319106

+86 13703116356

Fax:+86 311 68090963

Mail:hbkctc@sina.com

Talking about the welding performance of cast iron profiles?

Cast iron profiles have good cutting performance, uniform and compact structure, fine grain, good pressure resistance, excellent compactness, coating and wear resistance and wear resistance. The surface quality is smooth, the dimensional precision is high, the machining allowance is small, the hardness distribution is uniform, the tensile strength is high, and the mechanical properties are superior. Compared with the sand casting, the tensile strength is improved by 1-2 grades, the fatigue strength is increased by 50%, and the elastic modulus is improved. Increase by 30%. Reduce machining allowance by 20%-50% and save tool 70%. Increasing the material utilization rate by 12%-50%, the scrap rate caused by casting defects after processing is reduced from 20%-50% to 0-5%.

In addition to the above advantages, cast iron profiles. It also has the combination of high strength and high toughness, and good fatigue resistance. The comprehensive properties of cast iron profiles can significantly reduce costs.

Cast iron profiles have high carbon content, poor plasticity, uneven organization and poor weldability. When welding, the following problems are common:

1, easy to produce white mouth tissue after welding

2, easy to crack after welding

3, easy to produce pores after welding

Therefore, in production, cast iron is not used as a welding material. It is generally only used to weld cast iron casting defects and partially damaged cast iron parts. The welding repair of cast iron is generally carried out by gas welding or electrode arc welding.

Casting welding repair is often divided into two types: hot welding and cold welding.

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China

Add:No. 58 Fangbei Rd, Shijiazhuang

050011, Hebei province, China Tel: +86 311 85319106

Tel: +86 311 85319106  Mail:

Mail: